Holtop new developed 3D high efficiency counterflow heat recovery core is a unique heat exchanger (recuperator) innovative designed for air-to-air heat recovery core in comfortable fresh air ventilation systems. It is a true breakthrough in ventilation technology, making it possible to recover and efficiently recycle use generated energy drop energy consumption when air conditioning system heating or cooling rooms while optimizing the ventilation that is so crucial for a healthy indoor climate control system.

Holtop new developed 3D high efficiency counterflow heat recovery core is a unique heat exchanger (recuperator) innovative designed for air-to-air heat recovery core in comfortable fresh air ventilation systems. It is a true breakthrough in ventilation technology, making it possible to recover and efficiently recycle use generated energy drop energy consumption when air conditioning system heating or cooling rooms while optimizing the ventilation that is so crucial for a healthy indoor climate control system.

Holtop 3D High efficiency countercurrent heat exchangers are available in different product specifications suitable for residential and light commercial applications. It can be used in almost any ventilation system unit, maximizing indoor comfort and air quality while drastically reducing basic energy consumption and electricity costs. For the end-user, it not only supplies a good indoor climate control solution, improves the indoor air quality and fresh air ventilation, meanwhile drops energy consumption to save electricity costs. Moreover, it has reduced the consumption of fuels and greatly catered to the policies of energy conservation, emission reduction and environmental protection of the government.

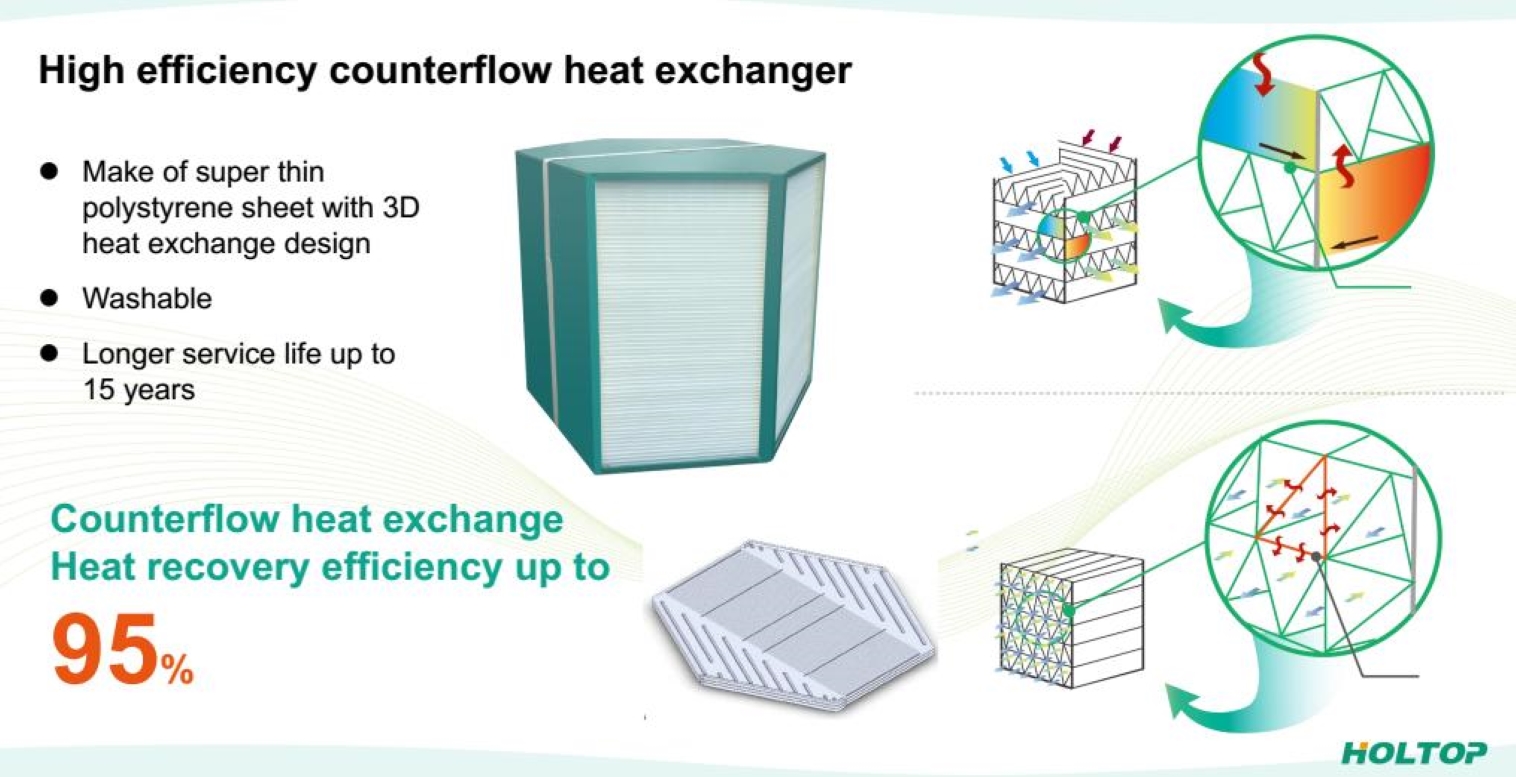

Features of 3D High Efficiency Counterflow Heat Exchanger (Recuperator)

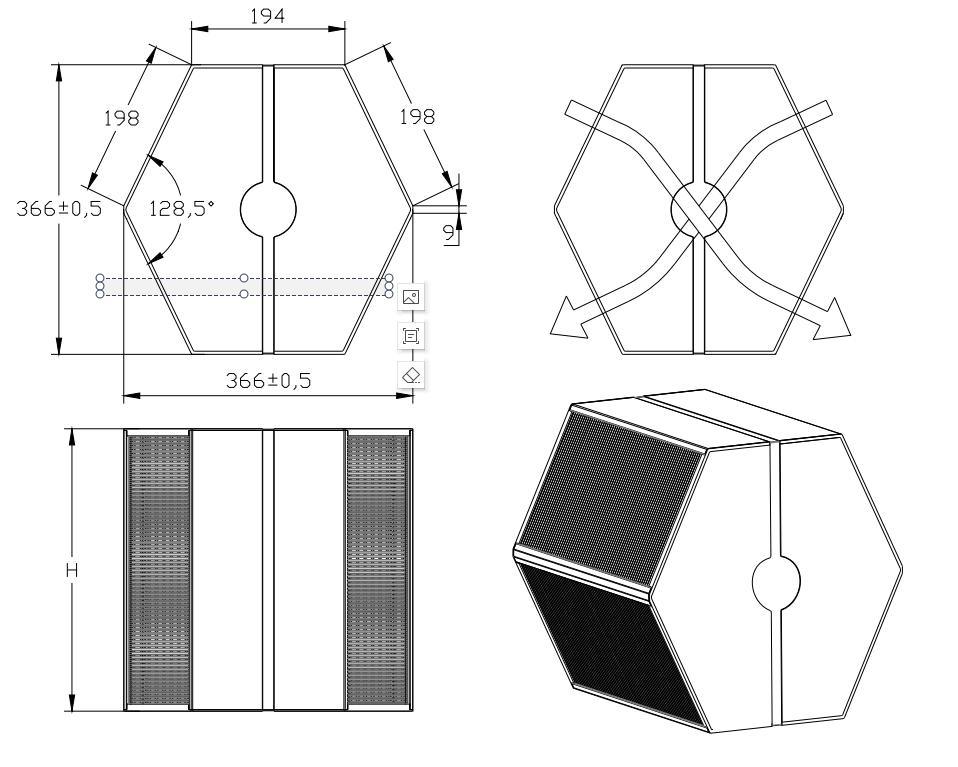

The appearance structure of the 3D counterflow high-efficiency heat exchanger is a hexagonal core, and the internal main channel structure is a triangle. This structure can fully ensure the maximum heat exchange area. The frame material of the heat exchanger is ABS, and the core material is special resin. This material has the characteristics of high thermal performance, good air tightness, tear resistance, oxidation resistance, and mildew resistance.

Working Principle

When the indoor temperature and humidity are different from outdoor, the two-way differential air stream will transfer energy and dampness, which call energy recovery.

In the counter-flow heat exchanger, airflows are passed by each other along with parallel special resin plates in a counter-flow direction. This allows achieving higher temperature efficiency than using crossflow heat exchanger core. Two neighbor special resin foils form a channel for fresh and exhaust air streams. Heat is transferred when the partial air streams flow crossly and partial air streams flow counter through the channels, and the fresh airflow and exhaust airflow are totally separated.

Ultra-high Heat Recovery Efficiency

The air flows counterflowly to extend the heat exchange time and make heat transfer more thoroughly. The heat recovery efficiency is up to 95%.

![performance parameter]](/uploads/zjkgzewstph.png)