Holtop Modular Cua Txias Chillers yog peb cov khoom tshiab tshaj plaws raws li ntau tshaj nees nkaum xyoo ntawm kev tshawb fawb & kev txhim kho, kev tsim cov thev naus laus zis thiab kev tsim khoom uas tau pab peb tsim cov chillers nrog kev ua haujlwm ruaj khov & txhim khu kev qha, zoo heev txhim kho evaporator & condenser tshav kub hloov efficiency. Nyob rau hauv txoj kev no nws yog qhov kev xaiv zoo tshaj plaws kom txuag tau lub zog, tiv thaiv ib puag ncig thiab ua tiav cov cua txias.

Holtop Modular Cua Txias Chiller tuaj yeem siv dav hauv tsev so, tsev kho mob, khw khw, tsev ua haujlwm, xinesmas, hlau kev lag luam, roj & tshuaj lom neeg kev lag luam, kev lag luam kev lag luam, kev lag luam hluav taws xob, hluav taws xob chaw nres tsheb thiab lwm yam.

Khoom Feature

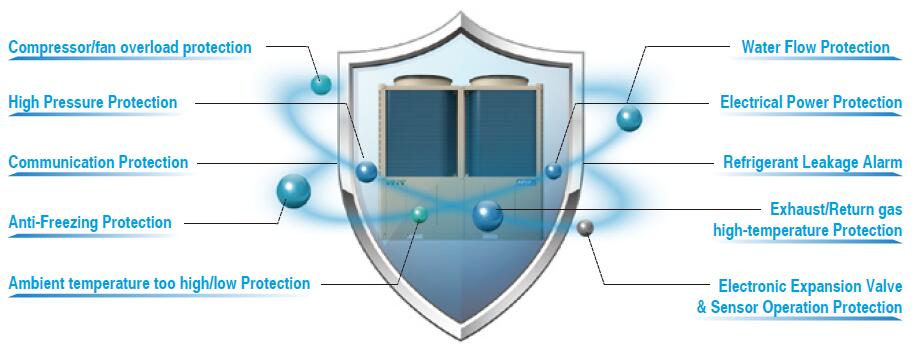

1. Kev tiv thaiv kev sib koom ua ke:

Tsim ntau tshaj 10 txoj haujlwm tiv thaiv kev nyab xeeb, uas tuaj yeem ua kom lub tshuab chiller thiab cov haujlwm ua haujlwm hauv kev tiv thaiv txhua qhov. Chav tsev tuaj yeem tswj tau los ntawm kev saib xyuas ntau yam sib txawv kom ntseeg tau tias chav nyob ruaj khov thiab ua haujlwm tau zoo.

2. Kev ntsuas kub ntau ntawm daim ntawv thov, tsis muaj kev txhawj xeeb ntawm kev ua haujlwm:

Chiller chav tsev yog tsim rau kev khiav hauj lwm nyob rau hauv ib tug dav sab nraum zoov kub ntau yam, los ntawm -20C ~ 48 ℃.

3. Chiller Chav Ua Haujlwm Thaum Ua Haujlwm:

Ib chav tsev yog tsim nrog ntau yam compressors. Thaum ib qho ntawm cov compressors tsis ua haujlwm, cov seem ntawm cov compressors hauv lub cev tseem tuaj yeem ua haujlwm ib txwm tsis cuam tshuam rau kev ua haujlwm ntawm tag nrho cov system.

4. Modular kev sib xyaw:

Lub chiller txais kev tsim qauv kev sib xyaw ua ke thiab tsis tas yuav teeb tsa tus tswv lossis sub-master unit. Txhua qhov sib xyaw ua ke tuaj yeem txuas tau qhov siab tshaj plaws ntawm 16 units, txawm tias lawv tau ua los ntawm cov qauv sib txawv, kom ua tau raws li qhov xav tau ntawm cov tsev sib txawv.

5. Kauj Ruam Pib:

Pib tag nrho cov chav nyob hauv cov kauj ruam, txhawm rau txo qis qhov pib tam sim no, txo qhov poob siab rau daim phiaj hluav taws xob, thiab tsis txhob cuam tshuam rau kev ruaj ntseg ntawm lwm yam khoom siv hluav taws xob.

6. Kev siv yooj yim:

Kev nqis peev: Ntxiv cov units ntxiv rau hauv kev sib xyaw ua ke txhua lub sijhawm, yooj yim rau ntau theem ntawm kev nqis peev

Kev thauj mus los: Lub ntim ntawm txhua chav tsev yog compact, tuaj yeem thauj mus los ntawm tus kheej, tsis xav tau lub crane ntawm qhov project, tuaj yeem txuag nqi tsheb thauj mus los.

Kev teeb tsa: Tsis xav tau chav tshuab lossis dej txias, tsuas yog qhov chaw uas muaj cua zoo. Cov kav dej yog tsim los ntawm sab ntawm chav tsev, uas tuaj yeem yooj yim rau kev sib txuas ntawm cov dej txias thiab txuag qhov chaw teeb tsa.

System: Nyob rau hauv cov dej circulating system, dhau li ntawm tus txheej txheem kev siv ntawm qhov tas mus li qhov system, nws yog xaiv tau los siv lub twj tso kua mis thawj zaug nrog ib tug kuj sib txawv khiav system, thiab lub kuj sib txawv ceev ceev tswj txee yog xaiv los xaiv.

7. Ntse Defrosting System:

Los ntawm kev hnov qab nrog ntau qhov sib txawv kom muaj kev txiav txim siab ntawm qhov xwm txheej ntawm frosting, lub chiller nws tus kheej tuaj yeem xaiv lub sijhawm zoo tshaj plaws los nkag lossis tawm defrosting, kom tsis txhob muaj qhov tsis txaus defrosting lossis dhau defrosting. Hauv cov txheej txheem duplex, cov chav nyob tuaj yeem ua tiav lwm yam defrosting. Thaum cua sov nyob rau hauv qhov tsis tshua muaj kub, teeb tsa phau ntawv defrosting rau kev ua tau zoo dua.

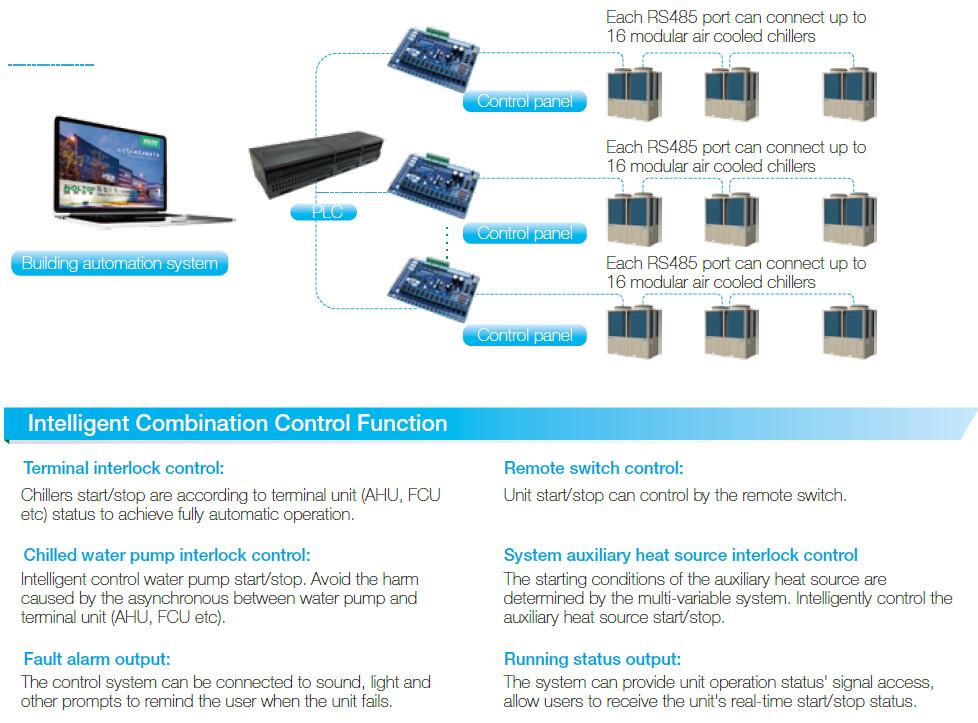

8. Intelligent PLC Tswj System:

PLC tswj qhov system ua ke nrog qhov yooj yim thiab yooj yim ntawm kev tswj cov kab hluav taws xob thiab qhov zoo ntawm pawg tswj hwm hauv nruab nrab kom ua tiav cov chiller pawg tswj hwm hauv nruab nrab. Ib qho PLC tswj qhov system tuaj yeem tswj 1 txog 8 pawg. Txhua pawg tuaj yeem tswj tau 1 txog 16 daim ntawm cov tshuab chillers. Lub kaw lus tuaj yeem tswj tau txog 128 modular chillers. Lub kaw lus tswj kuj muab ntau yam nta xws li pab pawg hloov pauv, hloov kho qhov kub thiab txias, qhib / tawm tswj, thiab lwm yam los txais yuav ntau daim ntawv thov.

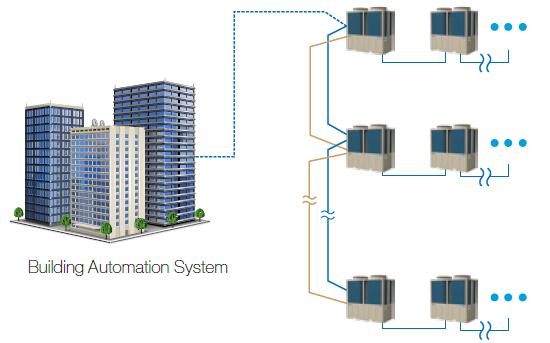

9. Pub dawb rau Tsev Automation System:

Standard RS485 lub tsev kev sib txuas lus interface los nrog qhib kev nkag mus rau tus qauv ModBus kev sib txuas lus raws tu qauv. Cov cuab yeej tuaj yeem txuas tau yooj yim rau kev tswj hwm lub tsev (BAS) rau kev tswj hwm hauv nruab nrab, yooj yim kom ua tiav cov kev tswj hwm ntse, zam kev tsis tsim nyog siv hluav taws xob pov tseg, thiab txuag cov nqi cua txias.

Holtop Modular Cua Txias Chiller Parameters:

| KHOOM PARAMETER | |||||

| Qauv / Specification | HFW-65HA1 | HFW-65HA1-L | HFW-130HA1 | HFW-130HA1-L | |

| Hom kub li qub | Yam tsawg-kub | Hom kub li qub | Yam tsawg-kub | ||

| Nominal txias peev (KW) | 65 | 63 | 130 | 130 | |

| Nominal cua sov muaj peev xwm (KW) | 71 | 71 | 142 | 141 | |

| Txias | Rated tag nrho input zog (KW) | 19.5 Nws | 18.7 ib | 39 | 37.7 ib |

| Cua sov | Rated tag nrho input zog (KW) | 21 | 19.5 Nws | 42 | 38.8 ib |

| Nominal low-temperature cooling peev (KW) | / | 52 | / | 100 | |

| Tag nrho cov nominal low-temperature cua sov input zog (KW) | / | 18.6 ib | / | 37 | |

| Qhov hluav taws xob | 380V / 3N ~ 50Hz | ||||

| Cov tub yees | R410A | ||||

| Throttle qhov chaw | Electronic expansion valve | ||||

| Compressor | Hom | Hermetic scroll | |||

| Qty | 2 | ||||

| Ntxuam | Hom | Axial low suab ntxuam | |||

| Lub zog (kw) | 0.9 * 2 | 1.5 * 2 | |||

| Airside tshav kub exchanger | Cua ntws (m³ / h) | 14000 * 2 | 19500 * 2 | ||

| Hom | High-efficient finned tshav kub pauv | ||||

| Waterside heat exchanger | Nominal dej ntws (m³ / h) | 11.5 ib | 11.5 ib | 22.5 ib | 22.5 ib |

| Hom | High-efficient plhaub & raj kub exchanger | ||||

| Dej siab poob siab (kPa) | 30 | 40 | |||

| Dej inlet / qhov hluav taws xob txuas yeeb nkab | DN 50 | DN 65 | |||

| Qhov Loj (W * H * D) | 1810 * 960 * 2350 hli | 2011 * 1100 * 2300 hli | |||

| Net nyhav (kg) | 580 | 600 | 1000 | 1050 | |