Popular Design for Plate Heat Exchanger Core - Plate Fin Type Crossflow Total Heat Exchanger – Holtop Detail:

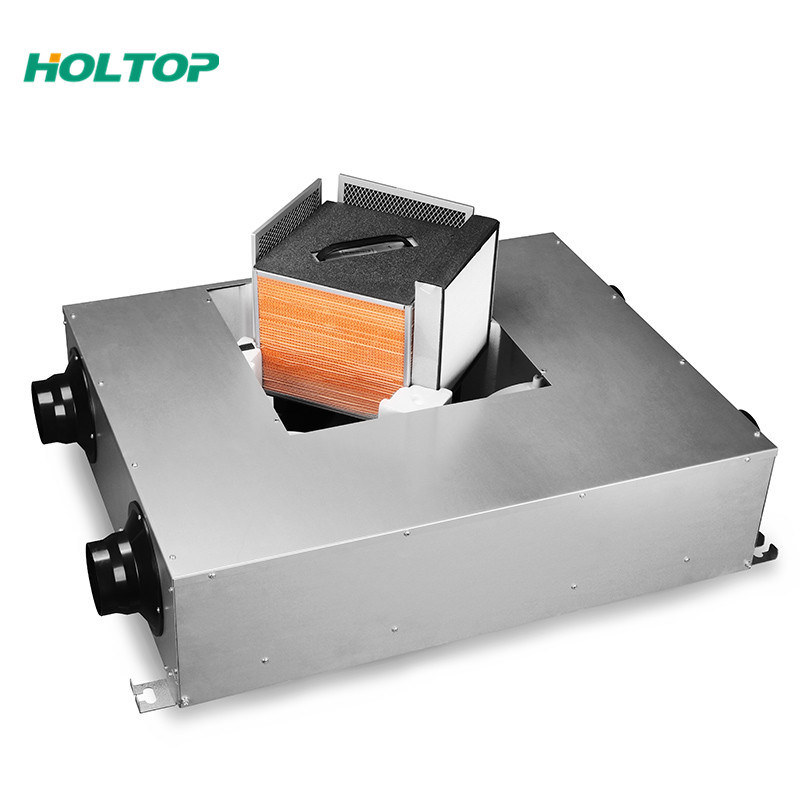

HOLTOP Plate Fin Type Crossflow Total Heat Exchanger

Holtop Cross-flow Plate Fin Total Heat Exchangers ( Enthalpy Recovery core for energy recovery ventilator)

Total heat exchanger is made of ER paper which is featured by high moisture permeability, good air tightness, excellent tear resistance, and aging resistance. The clearance between the fibers is very small, so only the moisture molecules of small diameter can go through, the odor molecules of larger diameter are unable to pass through it. By this means, the temperature and humidity can be recovered smoothly, and prevent the pollutants infiltrating to the fresh air.

Main Feature:

1. Made of E.R. paper, which is featured by high moisture permeability, good air tightness, excellent tear resistance, and aging resistance.

2. Structured with flat plates and corrugated plates.

3. Two air streams flow crossly.

4. Suitable for room ventilation and industrial ventilation system.

5. Heat recovery efficiency up to 85%

Working principle

The flat plates and the corrugated plates form channels for fresh or exhaust air stream. When the two air steams passing through the exchanger crossly with temperature difference, the energy is recovered.

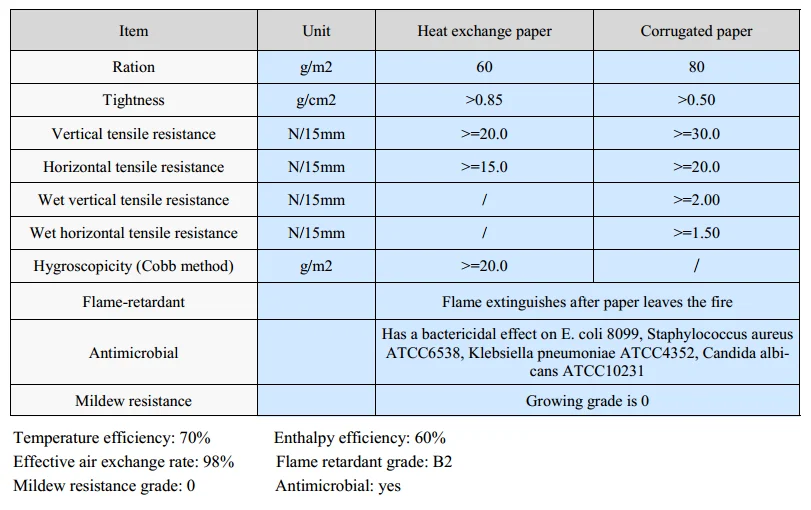

Performance index

E.R. paper performance introduction

Heat exchange paper: for heat and moisture exchange, the main performance standards are diathermancy, moisturepenetrability and air permeability. Corrugated paper: to construct the frame for the heat exchanger, flowing passages of the air stream.

Anti-bacteria and mold prevent performance

The bacteria exists in the damp air, when air goes through the heat exchanger, bacteria may stick on the walls of the exchanger. If the heat exchanger doesn’t have the anti-bacteria ability, it will grow on the inside wall, and then blown into indoor, which will cause indoor air pollution. That is why the anti-bacteria performance is required. The ability of bacterial growth inhibition and killing bacteria, to prevent the production of mold, is an important factor of heat exchanger paper. By adding the bactericides to the surface of paper and the anti-bacteria agents to the slurry, the heat exchanger has abilities to kill bacteria (such as Escherichia coli and staphylococcus) and inhibit fungal (such as Candida albicans) and prevent the bacteria and germ spreading in the air. Holtop heat exchanger paper was tested by Guangzhou Industry Microbe Test Center, and shown the antibacterial effect, and its mildew grade is 0.

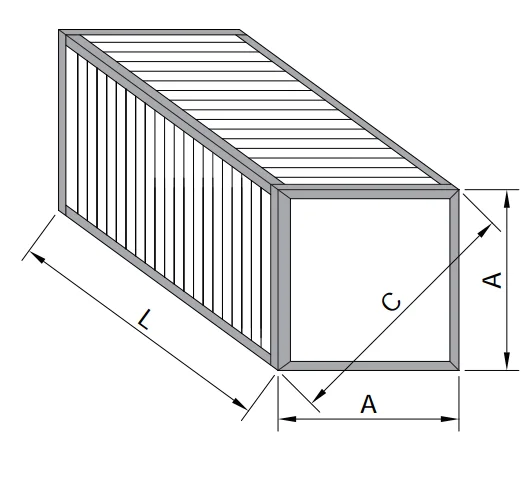

Product Specification

The heat exchange paper and corrugated paper are adhesived with waterborne binder, the core and cover are sealed with special sealant to total separate the supply air and exhaust air, in order to keep the structure strength and air tightness and prevent the cross contamination. It is widely applied and the maximum temperature should not exceed 100 C.

For size A within 500mm and the size L within 600mm, the heat exchanger is built in one module. For size A bigger

than 500mm and size L bigger than 600mm, the heat exchanger is built in multi-modules.

| Model | A (mm) | B (mm) | C (mm) | Optional corrugation height (mm) | Remarks |

| HBT-W168/168 | 168 | ≤500 | 240 | 2.0, 2.5 | One module |

| HBT -W202/202 | 202 | ≤500 | 288 | 2.0, 2.5 | |

| HBT -W222/222 | 222 | ≤500 | 317 | 2.0, 2.5 | |

| HBT-W250/250 | 250 | ≤700 | 356 | 2.0, 2.5, 3.5 | |

| HBT-W300/300 | 300 | ≤700 | 427 | 2.0, 2.5, 3.5 | |

| HBT -W350/350 | 350 | ≤700 | 498 | 2.5, 3.5 | |

| HBT -W372/372 | 372 | ≤700 | 529 | 2.5, 3.5 | |

| HBT -W400/400 | 400 | ≤700 | 568 | 2.5, 3.5 | |

| HBT -W472/472 | 472 | ≤550 | 670 | 3.5 | |

| HBT -W500/500 | 500 | ≤550 | 710 | 3.5 | |

| HBT -W552/552 | 552 | ≤550 | 783 | 3.5 | |

| HBT -W600/600 | 600 | ≤550 | 851 | 3.5 | |

| HBT -W652/652 | 652 | ≤550 | 925 | 3.5 | |

| HBT -W700/700 | 700 | ≤550 | 993 | 3.5 | Multi-module combined |

| HBT -W800/800 | 800 | ≤550 | 1134 | 3.5 | |

| HBT-W1000/1000 | 1000 | ≤450 | 1417 | 3.5 | |

| HBT-W1200/1200 | 1200 | ≤450 | 1702 | 3.5 | |

| HBT -W1400/1400 | 1400 | ≤450 | 1985 | 3.5 | |

| HBT -W1600/1600 | 1600 | ≤450 | 2265 | 3.5 |

Applications

Used in comfortable air conditioning ventilation system and technical air conditioning ventilation system. Supply air and exhaust air totally separated, heat recovery in winter and cold recovery in Summer

-Direct air to air energy exchange

-Ideal for both residential and commercial application

- Suitable for airflow 300-60000 m3/h.

- Previous: Cross Counterflow Heat Exchangers

- Next: Sensible Plate Heat Exchanger

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our best company and solution for Popular Design for Plate Heat Exchanger Core - Plate Fin Type Crossflow Total Heat Exchanger – Holtop , The product will supply to all over the world, such as: San Francisco , St. Petersburg , Morocco , Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.