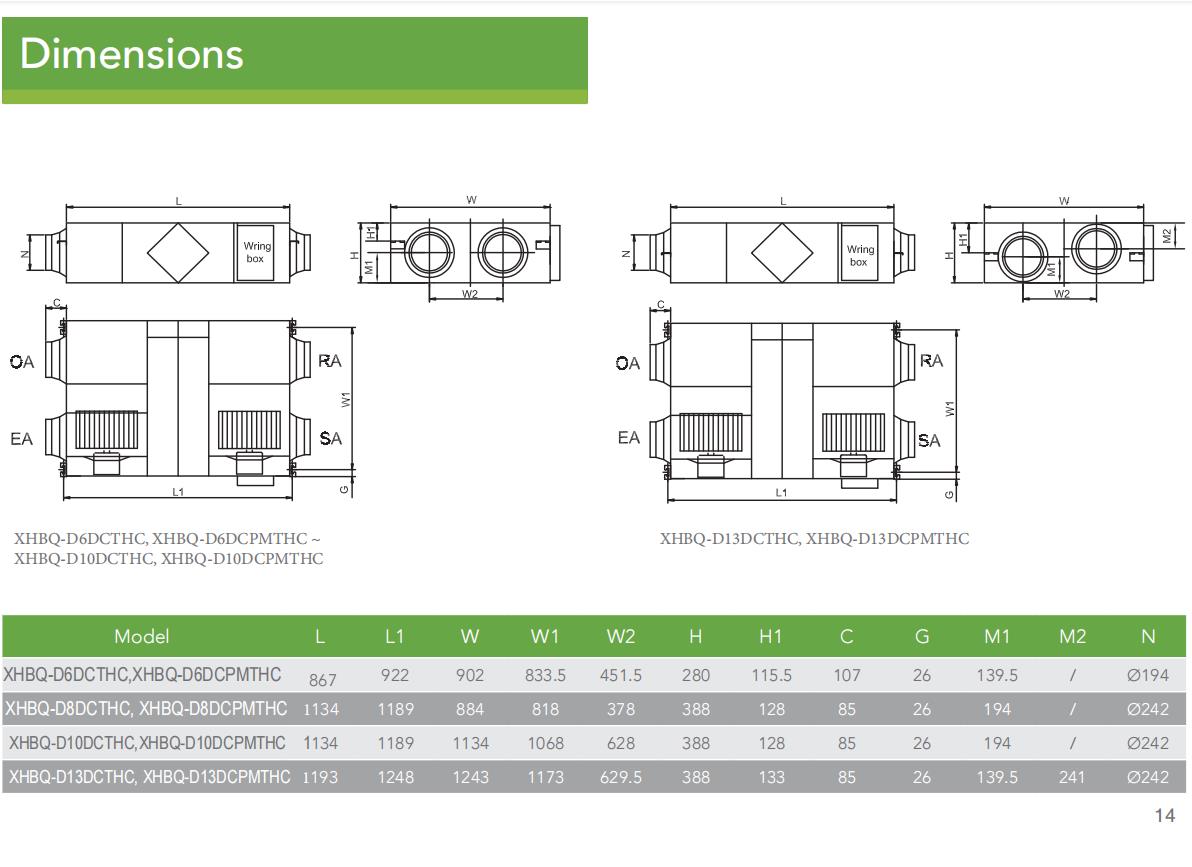

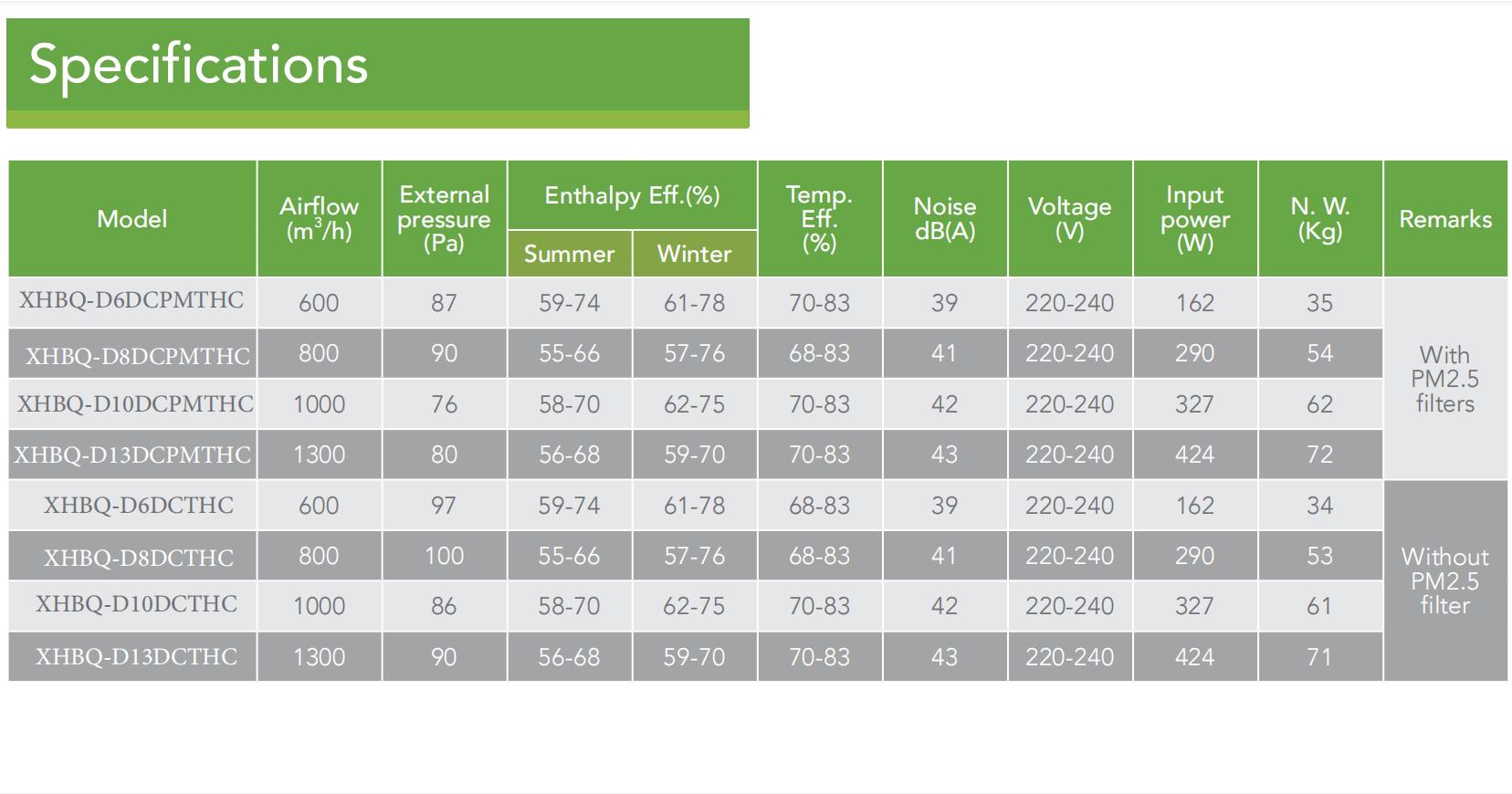

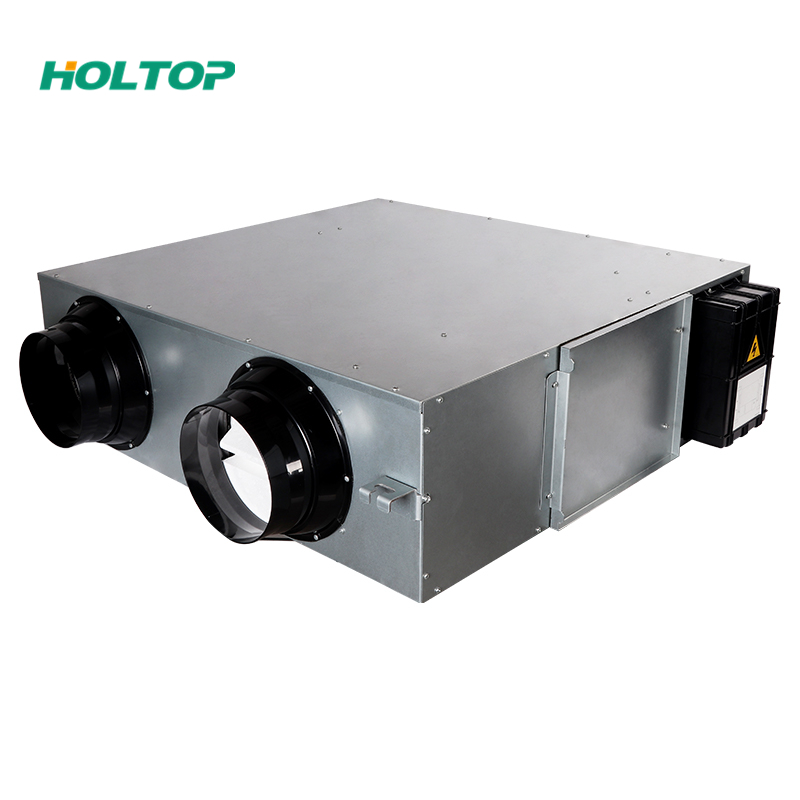

professional factory for Single Room Hrv Unit - DC Motor THC Series Commercial Suspended Energy Recovery Ventilation System (ERVs 600~1300 m3/h) – Holtop Detail:

HOLTOP CEILING MOUNTED ERV WITH BYPASS FUNCTION AND PM2.5 FILTRATION

Fresh air supply + High Efficiency Purification+ Energy recuperative ( reducing running cost of cooling or heating air conditioning system)

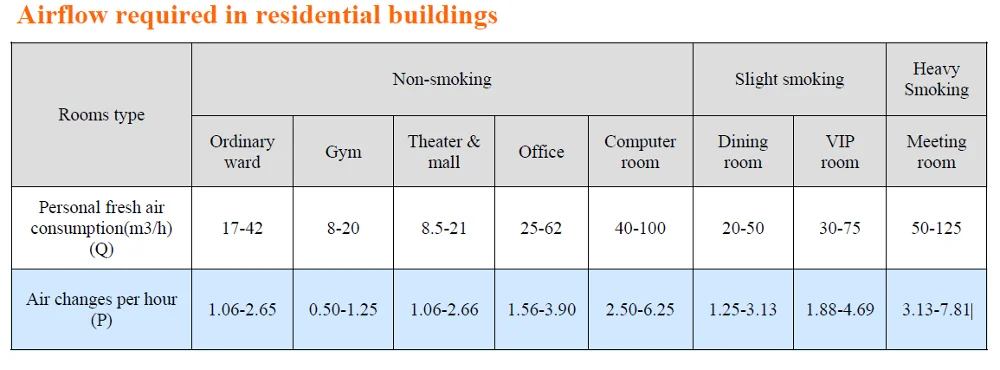

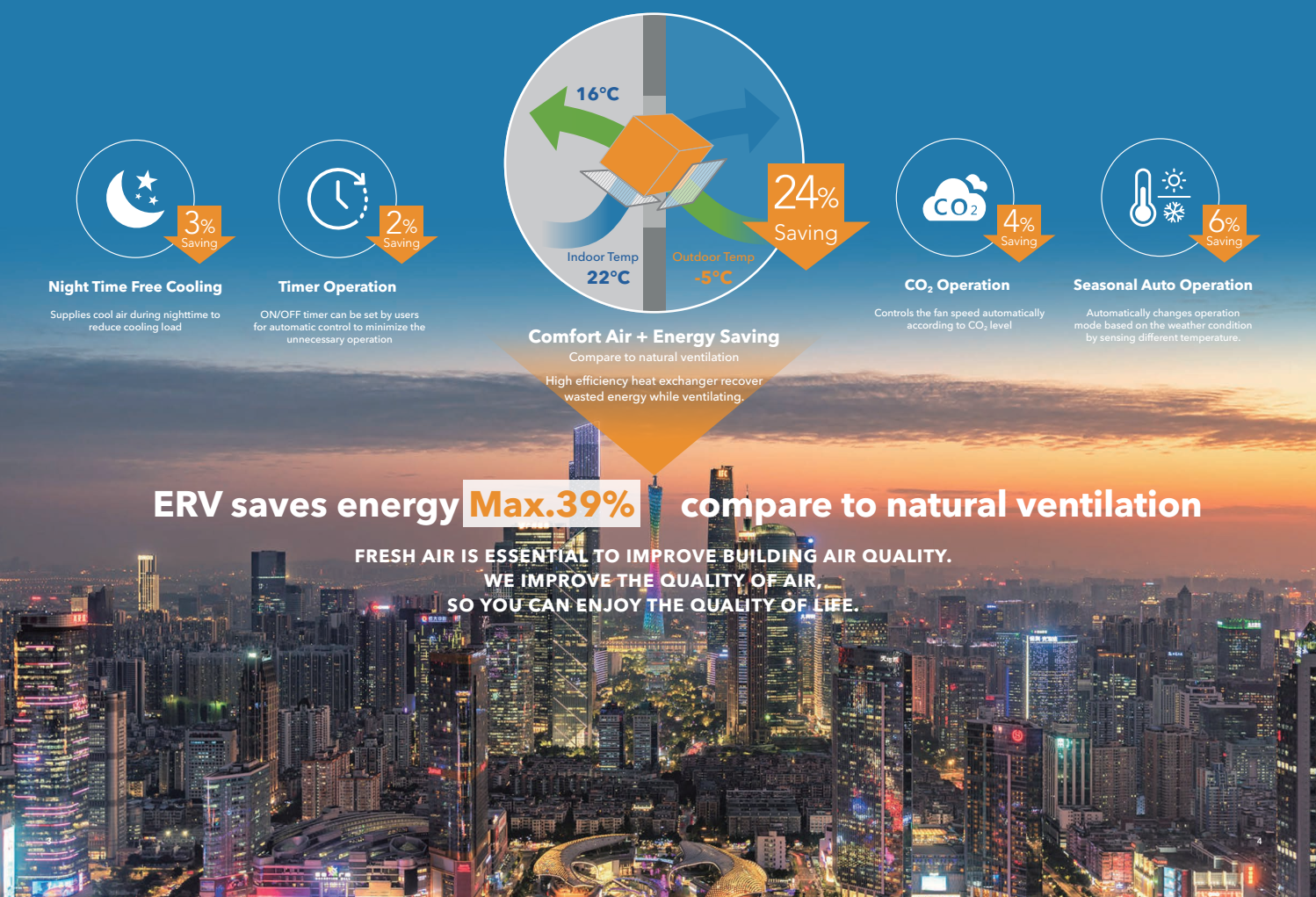

Energy recovery ventilation (ERV) is the energy recovery process of exchanging the energy contained in normally exhausted building or space air and using it to treat (precondition) the incoming outdoor ventilation air in residential and commercial HVAC systems. During the warmer seasons, the system pre-cools and dehumidifies while humidifying and pre-heating in the cooler seasons. The benefit of using energy recovery is the ability to meet the ASHRAE ventilation & energy standards, while improving indoor air quality and reducing total HVAC equipment capacity. |

|

| Higher Energy Efficiency and Ecology by Powerful Motors HOLTOP XHBQ-D*DCPMTHC Series Commercial energy recovery ventilators is built with higher efficiency BLDC motors, power consumption is reduced by up to 70%, resulting in significant energy saving. Advanced Intelligent control is suitable for most of the projects’ air volume and ESP requirements. |

|

|

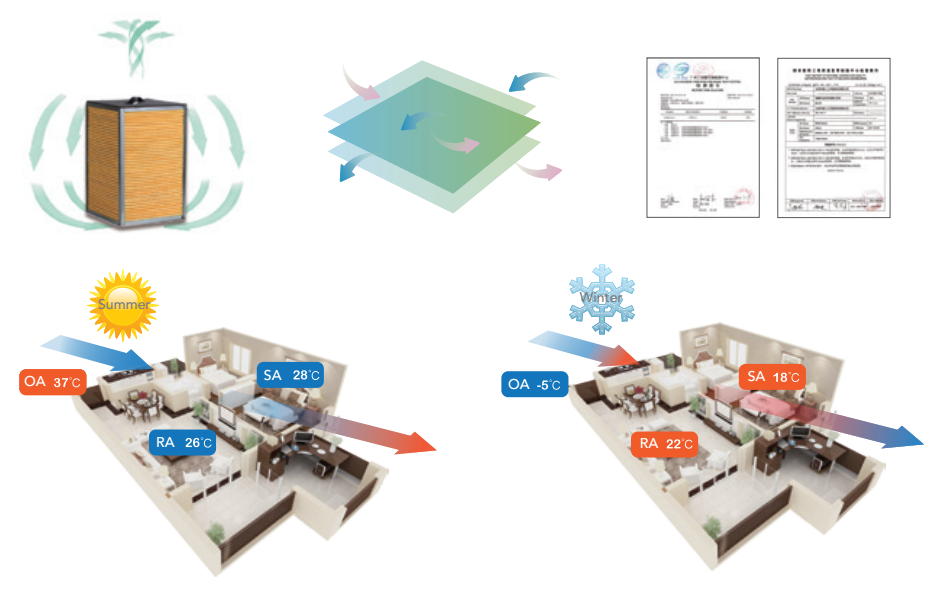

| Higher efficiency with Holtop 3rd generation enthalpy exchanger (Total heat Recuperator)Holtop crossflow enthalpy exchanger, heat recovery efficiency up to 82% in winter, the allowance of moisture exchange between fresh air and exhaust air make a soft indoor temperature and humidity.The 3rd generation enthalpy exchanger is made of the latest nanofiber structure to ensure higher efficiency. The heat exchange materials are mildew resistance and fire retardant. |

Good thermal insulation

The whole series is integrated with EPS structure, effectively preventing condensation, and improving thermal insulation and saving energy consumption.

. |

Product detail pictures:

Related Product Guide:

Our organization has been focusing on brand strategy. Customers' gratification is our greatest advertising. We also source OEM provider for professional factory for Single Room Hrv Unit - DC Motor THC Series Commercial Suspended Energy Recovery Ventilation System (ERVs 600~1300 m3/h) – Holtop , The product will supply to all over the world, such as: Spain , Greek , Jakarta , All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!